Weldoflange Suppliers

ASME B16.5 Weld Outlet Flange

ASME B16.5 Weldoflange: Dimensions | Specifications | Material Grade | Standards | About Weld Outlet Flange | All Product Types

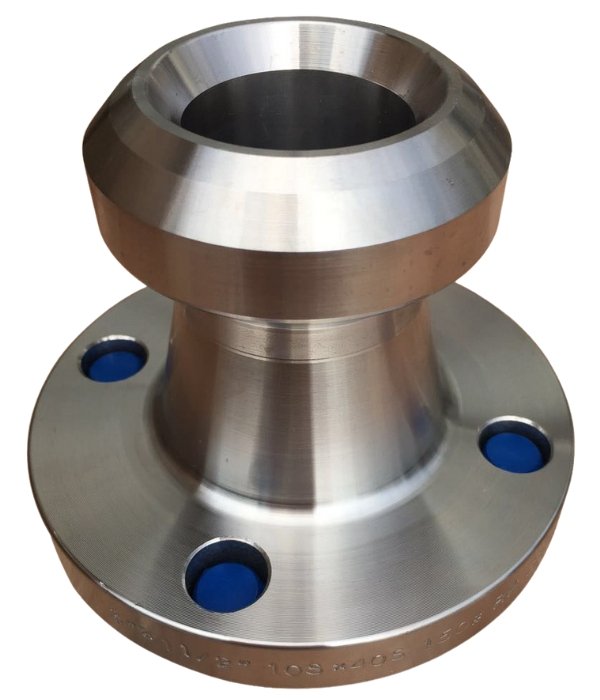

Nutech Overseas is a trusted manufacturer and exporter of high-quality Weldoflanges, designed to provide a strong and compact branch connection in high-pressure piping systems. A Weldoflange combines the features of a weld neck flange and a weldolet, integrating both into a single forged component. This eliminates the need for two separate fittings, reducing welding time, improving structural integrity, and ensuring precision alignment.

Weldoflanges are widely used for branch pipeline connections at 90° angles and are ideal for systems involving high pressure, vibration, and thermal stress. These flanges are particularly suitable for compact spaces where conventional piping connections like tees are not feasible. Available in Standard and Reducing Bore types, they ensure smooth flow transition, minimize turbulence, and reduce fatigue at the weld zone.

We manufacture ASME B16.5 Weldoflanges in pressure ratings from Class 150 to Class 2500 and in sizes ranging from ½″ NB to 24″ NB. Our range includes Butt Weld and Socket Weld outlet flanges, machined with precision to ensure tight tolerances and optimal sealing performance.

Available face types include Raised Face (RF) and Ring Type Joint (RTJ). Every Weldoflange is inspected for dimensional accuracy, material traceability, and surface finish, and can be supplied with certification as per EN 10204 Type 3.1 / 3.2, NACE MR0175, PED, and other international standards.

Whether for oil & gas platforms, petrochemical plants, pressure vessels, refineries, or power generation units, Nutech’s Weldoflanges are engineered to perform under extreme operating conditions.

As a global exporter, we supply weld outlet flanges that meet custom drawing specifications, mating flange standards, and project MTOs — serving EPC contractors and industrial clients across UAE, Saudi Arabia, Germany, South Africa, USA, Qatar, and Southeast Asia.

ASME B16.5 Forged Weldoflanges for Branch Pipeline Connections in Class 150 to 2500 Systems.

For complete technical details, including dimensions, pressure rating classes, weight charts, sizes, tolerances, and material specifications of our ANSI B16.5 Weldo Flanges, please download the full Catalog PDF below.

Standard and Reducing Weldoflanges with Raised Face & RTJ Ends for Oil, Gas, and Power Piping Projects.

Technical Specifications of Weldoflanges

| Specification | Details |

|---|---|

| Flange Type | Weldoflange – Integrates a Weld Neck Flange and Weldolet |

| Design Standard | ASME B16.5, B16.25 (welding ends), MSS-SP-97 (reference) |

| Size Range | ½″ NB to 24″ NB (DN15 to DN600) – Larger sizes available on request |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500 / PN10 to PN400 |

| End Connection | Butt Weld (standard) or Socket Weld (on request) |

| Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face |

| Bore Type | Standard Bore and Reducing Bore (customizable) |

| Surface Finish | Stock Finish, Spiral Serrated, Smooth Machined (Ra 3.2–6.3 μm) |

| Inspection & Testing | Hydro Test, PMI, UT/MPI, Visual QC, Dimensional Inspection |

| Certifications | EN 10204 Type 3.1 / 3.2, NACE MR0175, ISO 9001:2015, PED 2014/68/EU, IBR (if required) |

| Application Industries | Oil & Gas, Petrochemical Plants, Refineries, Boilers, High-Pressure Piping |

| Origin | Made in India (by Nutech Overseas) |

| Export Network | USA, Europe, and Middle East |

Complete Material Grade Chart - Class 150 Weldo Flange

| Material Category | Weld Outlet Flange Grades |

|---|---|

| Stainless Steel Weldoflange | ASTM A182 F304 / F304L / F304H, F316 / F316L / F316Ti, F310, F309S, F317 / F317L, F321 / F321H, F347 / F347H, F904L, ASTM A351 CF3 / CF3M / CF8 / CF8M / CF8C, DIN 1.4301, 1.4306, 1.4307, 1.4311, 1.4401, 1.4404, 1.4408, 1.4409, 1.4541, 1.4571, 1.4550, 1.4435, 1.4539 |

| Duplex Steel Weldoflange | ASTM A182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61, UNS S31803 / S32205 |

| Super Duplex Steel Weldoflange | ASTM A182 F53 / F55 / F57 / F59 / F60 / F61, UNS S32750 / S32760 |

| Carbon Steel Weldoflange | ASTM A105 / A105N, ASTM A350 LF2, ASTM A694 F52 / F56 / F60 / F65 / F70 / F80, ASTM A216 WCB, DIN 1.0460 / 1.0402 / 1.0619, Die Steel, Mild Steel |

| Alloy Steel Weldoflange | ASTM A182 F5 / F9 / F11 / F12 / F22 / F91, AISI 4130 / 4140 |

| Nickel Alloy Weldoflange | Nickel 200 / 201, ASTM B564 |

| Monel Weldoflange | Monel 400 (UNS N04400), Monel K500 (UNS N05500), ASTM B564 |

| Inconel Weldoflange | Inconel 600 / 601 / 625 / 690 / 718 / 783 / X750, ASTM B564 |

| Incoloy Weldoflange | Incoloy 800 / 800H / 800HT (UNS N08800), Incoloy 825 (UNS N08825), Incoloy 925, ASTM B564 |

| Hastelloy Weldoflange | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X, ASTM B564 |

| Alloy 20 Weldoflange | Alloy 20 / 20Cb-3, Carpenter® 20, ASTM B462 |

| 254 SMO Weldoflange | SMO 254 / 6Mo, UNS S31254, DIN 1.4547, ASTM A182 |

| Copper Nickel Weldoflange | Copper Nickel 90/10 (C70600), 70/30 (C71500), UNS C71640, ASTM B61 / B62 / B151 / B152 |

| Copper Weldoflange | TP1, TP2, T1, T2, C10100–C12300, C14200–C17200, C21000–C71520, including C10930, C11000, C11400, C12000, C12200, C26000, C28000, C33000, C44300, C70600, etc. |

| Brass Weldoflange | Grades 3602, 2604, H59, H62, etc. |

| Aluminium Weldoflange | Aluminium Grades 5052, 6061, 6063, 2017, 7075, etc. |

| Titanium Weldoflange | ASTM B381 Gr.1 / Gr.2 / Gr.4 / Gr.5 / Gr.7, UNS R50250 / R50400 / R50550 / R50700 / R52400 / R53400 / R56320 / R56400 |

| Other Special Grades | Al6XN, Tin Bronze, Aluminium Bronze, Lead Bronze, Nimonic 75 / 80A / 90 |

International Flange Standards We Manufacture & Supply

A Weldoflange is a one-piece forged component that merges a weld neck flange with a weldolet outlet, specifically designed for creating 90° branch connections from a main run pipe. It simplifies complex piping layouts where space, integrity, and pressure handling are critical.

Key Differences vs. Traditional Branch Fittings:

- Weldoflange replaces two components — the weldolet + flange, reducing welding operations and risk of misalignment.

- Ensures stronger mechanical support due to its integral construction.

- Requires less space and less installation time, making it ideal for compact or congested systems.

- Delivers superior fatigue resistance in high-pressure or high-vibration lines.

Commonly used in oil & gas, power plants, and offshore applications where precision and pressure integrity are essential.

Proper welding and installation of Weldoflanges is critical to ensure pressure integrity, alignment, and long-term performance of the branch connection.

Key Welding Guidelines:

- Butt Weld End: The Weldoflange is beveled at the branch end to allow full penetration butt welding to the header pipe.

- Pre-Welding Prep: Ensure proper root gap, alignment, and bevel match. Clean all mating surfaces to prevent contamination.

- Welding Code Compliance: Follow WPS/PQR per ASME Section IX, with welders qualified under project specs.

- Non-Destructive Testing (NDT): Use UT, RT, MPI, or DPI as per project quality plan to ensure weld integrity.

- Post Weld Heat Treatment (PWHT): May be required for high-alloy or thick-wall materials to relieve stress.

Installation Notes:

- Ensure the Weldoflange face aligns properly with mating flange.

- Use correct gasket type (e.g., Spiral Wound or RTJ ring).

- Torque bolts per ASME PCC-1 to achieve uniform sealing.

These steps are critical in high-pressure environments like refineries, offshore rigs, and power plants where failure is not an option.

Weldoflanges are preferred in critical pipeline systems because they offer several mechanical and operational advantages over conventional fittings like weldolets + flanges or tees.

Key Advantages:

- Compact Design: Combines two components (weldolet and flange) into one, saving space and reducing system weight.

- Reduced Welding Time: Only one weld joint is needed, minimizing labor costs and reducing inspection complexity.

- Improved Structural Integrity: Integral forging means fewer stress concentration points and better fatigue resistance.

- Precise Alignment: Ensures perfect bore alignment between branch and header pipe, reducing turbulence and erosion.

- Leak-Proof Performance: Fewer joints = fewer potential leak paths, especially important in hazardous fluid service.

- Available in Reducing Type: Allows direct connection to smaller branch pipes without additional reducers.

Widely used in offshore platforms, petrochemical complexes, boiler systems, and FPSO vessels.

Yes, Weldoflanges can be fully customized to meet non-standard design requirements, especially in retrofit projects, offshore rigs, and modular systems where standard flanges won’t fit.

Common Customization Options:

- Non-Standard Drilling Patterns:

- Match legacy equipment or custom mating flanges

- Modified bolt-hole diameter, pitch circle diameter (PCD), or number of holes

- Offset Branch Angles:

- 90° is standard, but 45°, 60°, or custom angles can be machined on request

- Special Face Finishes:

- Serrated finish per Ra requirement

- Smooth face, spiral machined, or coated face (PTFE/Xylan)

- Custom Hub or Neck Lengths:

- Extended necks for insulation clearance or spool connection

- Tapered transition for smooth fluid dynamics

- Integration with Other Standards:

- ASME B16.5 × DIN or EN standards in hybrid piping systems

- Special pressure ratings above Class 2500 for critical zones

Nutech specializes in manufacturing project-specific Weldoflanges from client drawings, P&ID references, or reverse-engineered samples, with full material traceability and QC documentation.

Nutech Overseas is a global exporter of ASME B16.5 Weldoflanges, serving various industries including oil & gas, petrochemicals, shipbuilding, and power generation. With precision forging, strict quality control, and customizable options, our Weldoflanges are trusted in critical piping systems worldwide.

Major export destinations include:

- Middle East: United Arab Emirates (UAE), Saudi Arabia, Qatar, Oman, Kuwait, Bahrain

- Europe: Germany, Italy, Spain, Netherlands, Turkey

- Africa: South Africa, Egypt, Nigeria

- Asia-Pacific: Malaysia, Singapore, Indonesia, Philippines, Vietnam

- South Asia: Sri Lanka, Bangladesh

- Americas: United States (USA), Canada, Brazil

All Weldoflanges are supplied with EN 10204 3.1 / 3.2 certificates, NACE compliance, and custom packaging, with fast delivery via sea and air freight to meet project deadlines globally.

Browse The Products

Forged Fittings

Flanges

Buttweld Fittings