NORSOK Flanges Suppliers

L-005 Standard Manufacturers

NORSOK Standard Flanges: Dimensions | Specifications | Material Grade | Standards | About NORSOK L-005 Flange | All Product Types

NORSOK Flanges are specialized piping components engineered according to the NORSOK L-005 standard, a key specification developed by the Norwegian petroleum industry to enhance safety, efficiency, and uniformity in offshore and subsea oil & gas operations. These flanges are crucial for high-performance piping systems used in harsh environments, particularly in the North Sea and Arctic installations, where extreme pressures and temperatures are common. Unlike conventional flange standards, NORSOK-compliant flanges are designed to withstand not only mechanical stress but also severe corrosion due to seawater exposure and sour service conditions.

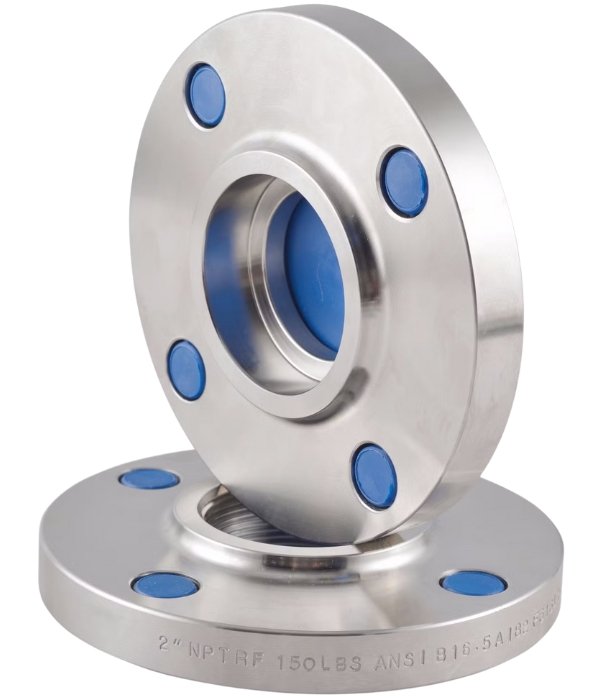

We supply a wide range of NORSOK standard flanges, including Weld Neck, Blind, Socket Weld, Threaded, Lap Joint, and Orifice flanges, available in Class 150 to Class 2500 pressure ratings and sizes ranging from ½″ NB to 48″ NB. These flanges conform to NORSOK L-005, along with complementary international requirements like ISO 15156 (NACE MR0175) for sour service, PED 2014/68/EU, and EN 1092-1 tolerances. Face finishes are available in Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), and custom machined designs depending on process requirements. Special surface finishes and sealing faces are offered for subsea bolting and hydrocarbon containment applications.

Materials offered include Carbon Steel (ASTM A105, A350 LF2), Stainless Steel (304/304L, 316/316L), Duplex (UNS S31803), Super Duplex (UNS S32750 / S32760), Inconel (625, 825), Alloy 20, Hastelloy C276, and other high-performance alloys, with full material traceability and certification. Each flange is supplied with inspection reports, ultrasonic testing (UT), hydro test data, and EN 10204 3.1 or 3.2 certificates, making them suitable for critical installations in offshore rigs, FPSOs, subsea manifolds, process modules, refineries, and LNG terminals.

As a global manufacturer and exporter of Norwegian standard flanges, we deliver NORSOK-compliant flanges to countries like Norway, UK, Netherlands, UAE, Saudi Arabia, Singapore, and Malaysia, supporting major EPCs and offshore contractors. We offer custom-machined NORSOK flanges based on project drawings or dimensional standards with tight machining tolerances and corrosion-resistant coatings. Whether you require standard stock items or engineered flange solutions tailored to offshore platform specifications, we ensure consistent quality, on-time delivery, and full compliance with Norwegian offshore regulations.

High-Performance NORSOK Standard Flanges for Offshore Platforms, Subsea Installations & Sour Service Projects.

For complete technical details, including dimensions, pressure rating classes, weight charts, sizes, tolerances, and material specifications of our NORSOK L-005 Standard Flanges, please download the full Catalog PDF below.

Trusted Manufacturer & Exporter of NORSOK L-005 Compliant Flanges – Designed for Critical Oil & Gas, Petrochemical, and Marine Systems.

Technical Specifications of NORSOK L-005 Flanges

| Specification | Details |

|---|---|

| Standard | NORSOK L-005, based on ISO 7005, EN 1759, and ASME B16.5/B16.47 as applicable |

| Flange Types | Weld Neck, Blind, Slip-On, Threaded, Socket Weld, Compact Flanges (CF), and RTJ types |

| Size Range | ½″ NB to 60″ NB (DN15 to DN1500) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500 | PN6 to PN400 |

| Face Types | Raised Face (RF), Ring Type Joint (RTJ), Compact Flange Face (as per NORSOK design) |

| Tolerances | As per ISO 27509 and NORSOK dimensional tolerances |

| Surface Finish | 3.2 – 6.3 μm (Stock Finish), Spiral Serrated, Smooth Face |

| Testing & Certification | EN 10204 Type 3.1 / 3.2, NORSOK M-650 Qualification, NACE MR0175/ISO 15156 |

| Application Sectors | Oil & Gas (Offshore & Onshore), Petrochemical, Marine Engineering, FPSOs, Subsea Installations |

| Coating Options | Rust Preventive Coating, PTFE, Hot Dip Galvanized, Epoxy Coating (On request) |

| Origin | Made in India (by Nutech Overseas) |

| Export Network | USA, Europe, and Middle East |

Complete Material Grade Chart - NORSOK L-005

| Material Category | NORSOK L-005 Flange Grades |

|---|---|

| Stainless Steel NORSOK Flange | ASTM A182 F304 / F304L / F304H, F316 / F316L / F316Ti, F310, F309S, F317 / F317L, F321 / F321H, F347 / F347H, F904L, ASTM A351 CF3 / CF3M / CF8 / CF8M / CF8C, DIN 1.4301, 1.4306, 1.4307, 1.4311, 1.4401, 1.4404, 1.4408, 1.4409, 1.4541, 1.4571, 1.4550, 1.4435, 1.4539 |

| Duplex Steel NORSOK Flange | ASTM A182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61, UNS S31803 / S32205 |

| Super Duplex Steel NORSOK Flange | ASTM A182 F53 / F55 / F57 / F59 / F60 / F61, UNS S32750 / S32760 |

| Carbon Steel NORSOK Flange | ASTM A105 / A105N, ASTM A350 LF2, ASTM A694 F52 / F56 / F60 / F65 / F70 / F80, ASTM A216 WCB, DIN 1.0460 / 1.0402 / 1.0619, Die Steel, Mild Steel |

| Alloy Steel NORSOK Flange | ASTM A182 F5 / F9 / F11 / F12 / F22 / F91, AISI 4130 / 4140 |

| Nickel Alloy NORSOK Flange | Nickel 200 / 201, ASTM B564 |

| Monel NORSOK Flange | Monel 400 (UNS N04400), Monel K500 (UNS N05500), ASTM B564 |

| Inconel NORSOK Flange | Inconel 600 / 601 / 625 / 690 / 718 / 783 / X750, ASTM B564 |

| Incoloy NORSOK Flange | Incoloy 800 / 800H / 800HT (UNS N08800), Incoloy 825 (UNS N08825), Incoloy 925, ASTM B564 |

| Hastelloy NORSOK Flange | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X, ASTM B564 |

| Alloy 20 NORSOK Flange | Alloy 20 / 20Cb-3, Carpenter® 20, ASTM B462 |

| 254 SMO NORSOK Flange | SMO 254 / 6Mo, UNS S31254, DIN 1.4547, ASTM A182 |

| Copper Nickel NORSOK Flange | Copper Nickel 90/10 (C70600), 70/30 (C71500), UNS C71640, ASTM B61 / B62 / B151 / B152 |

| Copper NORSOK Flange | TP1, TP2, T1, T2, C10100–C12300, C14200–C17200, C21000–C71520, including C10930, C11000, C11400, C12000, C12200, C26000, C28000, C33000, C44300, C70600, etc. |

| Brass NORSOK Flange | Grades 3602, 2604, H59, H62, etc. |

| Aluminium NORSOK Flange | Aluminium Grades 5052, 6061, 6063, 2017, 7075, etc. |

| Titanium NORSOK Flange | ASTM B381 Gr.1 / Gr.2 / Gr.4 / Gr.5 / Gr.7, UNS R50250 / R50400 / R50550 / R50700 / R52400 / R53400 / R56320 / R56400 |

| Other Special Grades | Al6XN, Tin Bronze, Aluminium Bronze, Lead Bronze, Nimonic 75 / 80A / 90 |

International Flange Standards We Manufacture & Supply

NORSOK flanges are designed to meet the rigorous demands of the offshore oil and gas sector, primarily in Norway and the North Sea. Unlike general ASME or EN flanges, NORSOK flanges follow the NORSOK L-005 specification, incorporating enhanced features for corrosion resistance, pressure integrity, and safety in hostile marine environments.

Key differences include:

- Compact flange designs to save space and weight, especially on offshore platforms.

- Stringent material quality and testing requirements (e.g., compliance with NORSOK M-650 for material manufacturers).

- Enhanced corrosion resistance through surface treatments and material selection suitable for sour service.

- Higher safety margins, including verification against ISO 15156 / NACE MR0175 for hydrogen sulfide environments.

- Mandatory documentation and traceability per NORSOK M-001 and M-650 for material and manufacturing processes.

These differences make NORSOK flanges a preferred choice for subsea, topside, and FPSO applications, where reliability and safety are critical.

While NORSOK flanges share certain dimensional similarities with international standards like ASME B16.5 or EN 1092-1, they are not always interchangeable due to specific technical and certification differences:

- Design Basis: NORSOK standards are developed for the Norwegian petroleum industry and focus on offshore safety, material traceability, and corrosion resistance, especially in harsh environments.

- Tolerances & Testing: They often require stricter dimensional tolerances, higher impact testing, and compliance with NACE MR0175 or ISO 15156.

- Gasket Compatibility: Gasket faces and pressure ratings may differ, causing misalignment or sealing issues with non-NORSOK systems.

- Documentation Requirements: NORSOK flanges usually demand EN 10204 3.1/3.2 certification, which may not be mandatory under other standards.

For critical offshore and subsea applications, always verify full compliance — mixing standards without engineering validation is not recommended.

NORSOK flanges are specifically engineered to meet the rigorous demands of the Norwegian oil and gas sector, but their usage has expanded into other high-risk, high-performance industries due to their robust specifications. They are commonly used in:

- Offshore Platforms & Subsea Installations

- FPSOs (Floating Production Storage & Offloading units)

- Petrochemical Plants

- Hydrogen and Ammonia Handling Units

- Refineries operating in Arctic or corrosive environments

Key reasons why NORSOK flanges are preferred:

- Stringent Material Quality: Typically specified in Duplex (UNS S31803), Super Duplex (UNS S32750), Inconel, and other high-alloy grades for extreme corrosion resistance.

- Enhanced Safety & Traceability: Comes with full traceability, third-party inspection reports, and EN 10204 3.2 certification when required.

- Standardized for Harsh Environments: Designed for extreme temperatures, pressures, and aggressive chemicals.

- Global Recognition: Though Norway-specific, many offshore EPC contractors and global energy firms mandate NORSOK-compliant products for reliability and long-term performance.

This wide industry acceptance stems from NORSOK’s commitment to safety, durability, and lifecycle cost efficiency.

NORSOK flanges are specially developed to meet the harsh demands of offshore oil and gas platforms, especially where sour service (H₂S exposure), high salinity, and temperature fluctuations are prevalent. To ensure long-term integrity under such conditions, the standard enforces stringent metallurgical and mechanical requirements:

Key material integrity factors include:

- NACE MR0175 / ISO 15156 Compliance: Materials are resistant to sulfide stress cracking (SSC), especially in wet H₂S environments.

- Corrosion-Resistant Alloys (CRA): Grades like Duplex (UNS S31803), Super Duplex (UNS S32750), Inconel 625, and 6Mo are preferred for their excellent pitting and crevice corrosion resistance.

- Low Carbon & Impact-Tested Materials: Flanges undergo Charpy V-notch testing at sub-zero temperatures (typically -46°C) to ensure toughness and prevent brittle fracture in Arctic and deepwater conditions.

- Controlled Microstructure & Inclusion Ratings: Ensures no metallurgical anomalies that can lead to stress cracking during service.

- Strict Heat Treatment & Manufacturing Control: Including solution annealing and forging traceability to meet NORSOK M-650/M-630 procedures.

These features make NORSOK flanges ideal for subsea systems, risers, pipelines, and topside equipment, where failure is not an option.

At Nutech Overseas, we proudly export high-quality NORSOK standard flanges to some of the most demanding offshore and subsea engineering markets across the globe. These include:

Major Export Destinations:

- Norway – For use in Statoil (Equinor) and other North Sea operations.

- United Arab Emirates (UAE) – Supplying to ADNOC and offshore EPC contractors.

- Saudi Arabia – For Aramco-approved projects and pipeline installations.

- Qatar – Used in LNG plants and offshore oil platforms.

- Kuwait & Oman – Trusted by petrochemical and refinery sectors.

- Singapore & Malaysia – For deepwater projects and FPSO units.

- United States (USA) – Meeting NORSOK and API crossover specifications.

- United Kingdom (UK) – For North Sea offshore and onshore installations.

All flanges are shipped with full material traceability, 3.1/3.2 certification, and packaging suited for international transport. We provide customized export documentation, marking as per project specs, and fast delivery timelines — making us a trusted global supplier of NORSOK-compliant flanges.

Browse The Products

Forged Fittings

Flanges

Buttweld Fittings