DIN Flanges Suppliers

DIN 2501, 2527, 2633, 2635

DIN 2501 Standard Flanges: Dimensions | Specifications | Material Grade | Standards | About DIN Flange | All Product Types

DIN flanges, defined under the standards of the Deutsches Institut für Normung (DIN), represent one of the most widely accepted flange systems across Europe, the Middle East, and export-focused industrial projects worldwide. These flanges are classified based on pressure ratings (PN6 to PN400) and nominal sizes (DN10 to DN2000), and are engineered for optimal performance in fluid control, mechanical strength, and long-term sealing reliability. The DIN system provides standardized drilling templates, face finishes, and dimensional tolerances that ensure compatibility in global engineering and piping solutions.

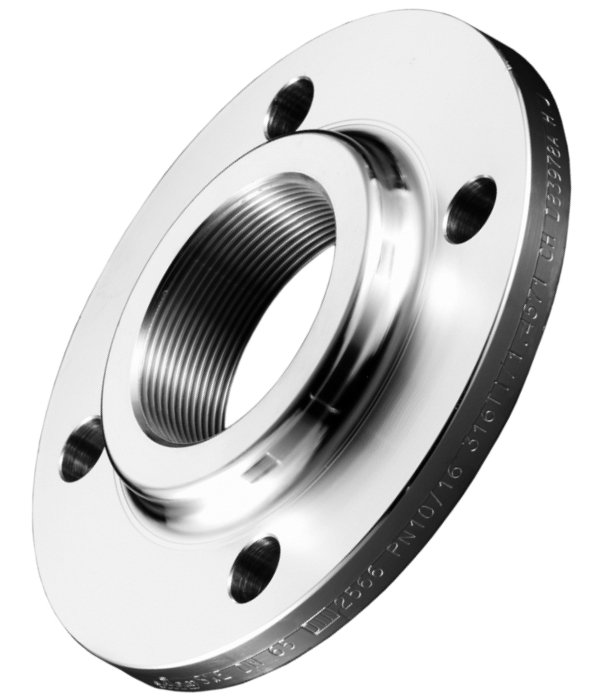

At Nutech, we offer a wide selection of DIN-compliant flanges including weld neck, slip-on, blind, threaded, lap joint, and integral flanges—manufactured according to key DIN standards such as DIN 2501, 2527, 2573, 2566, 2633, 2634, 2635, 2636, and 2638. Our flanges are available in pressure classes PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, PN250, and PN400, making them suitable for both low-pressure utility lines and high-pressure process systems. We serve a variety of sectors including water treatment, chemical processing, shipbuilding, energy production, and HVAC installations.

Our DIN flanges are manufactured using high-quality carbon steel, stainless steel, alloy steel, and special alloys, machined to precise dimensions using CNC-controlled processes to ensure superior fit-up and sealing performance. Available face types include raised face (RF), flat face (FF), and tongue & groove (T&G) based on the design and gasket compatibility. In addition to standard production, we also offer custom machining, drilling templates, and special surface finishes based on project specifications.

We ensures every DIN flange meets strict quality standards through non-destructive testing (NDT), visual QC, hydro testing, and dimensional verification. All flanges can be supplied with EN 10204 Type 3.1 or 3.2 certificates, complying with PED 2014/68/EU, ISO 9001:2015, and other industry-specific standards. Our global export network covers the UAE, Saudi Arabia, Germany, Italy, Spain, Egypt, and several European and Southeast Asian countries, with packaging designed to protect flanges during international logistics and long-term storage.

Whether your requirement is for a full pipeline flange package or a replacement flange for DIN-standard systems, Nutech is your trusted manufacturer and exporter, delivering precision-made, performance-assured flanges for every industrial challenge.

DIN Standard Flanges – Technical Dimensions, Tolerances, PN Pressure Ratings, Drilling Templates, and Surface Finish Requirements.

For complete technical details, including dimensions, pressure rating classes, weight charts, sizes, tolerances, and material specifications of our DIN 2527 Standard Flanges, please download the full Catalog PDF below.

Leading Manufacturer and Global Exporter of DIN 2501, 2527, 2633, 2635 Flanges in PN6 to PN400, Complying with European Industrial Standards.

Technical Specifications of DIN Standard Flange

| Specification | Details |

|---|---|

| Standards Covered | DIN 2501, DIN 2527, DIN 2633, DIN 2635, DIN 2634, DIN 2573, DIN 2566 |

| Flange Types | Weld Neck (Type 11), Blind (Type 05), Slip-On (Type 01), Threaded (Type 13), Loose Flanges (Type 21/34), Integral (Type 36) |

| Size Range | DN10 to DN2000 (⅜″ to 80″) |

| Pressure Ratings | PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN400 |

| Face Types | Raised Face (RF), Flat Face (FF), Tongue & Groove, Male & Female |

| Drilling Templates | As per DIN EN 1092-1 specifications and compatible with standard gasket types |

| Dimensional Tolerances | Conforming to DIN EN 1092-1 tolerance class A or B as specified |

| Surface Finish | Stock Finish, Serrated Finish, Smooth Finish – 3.2 to 6.3 μm (Ra) |

| Applications | Water Supply, Petrochemical, Power Plants, Oil & Gas, Marine, Paper & Pulp, Offshore Projects |

| Certification | EN 10204 3.1 / 3.2, PED 2014/68/EU, ISO 9001:2015, CE Marking |

| Application Industries | Water Supply, Oil & Gas, Marine, HVAC, Petrochemical, Power Generation, Fire Protection, Pulp & Paper |

| Origin | Made in India (by Nutech Overseas) |

| Export Network | USA, Europe, and Middle East |

Complete Material Grade Chart - DIN 2635 Flange

| Material Category | PN10 DIN 2501 Flange Grades |

|---|---|

| Stainless Steel DIN Flange | ASTM A182 F304 / F304L / F304H, F316 / F316L / F316Ti, F310, F309S, F317 / F317L, F321 / F321H, F347 / F347H, F904L, ASTM A351 CF3 / CF3M / CF8 / CF8M / CF8C, DIN 1.4301, 1.4306, 1.4307, 1.4311, 1.4401, 1.4404, 1.4408, 1.4409, 1.4541, 1.4571, 1.4550, 1.4435, 1.4539 |

| Duplex Steel DIN Flange | ASTM A182 F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61, UNS S31803 / S32205 |

| Super Duplex Steel DIN Flange | ASTM A182 F53 / F55 / F57 / F59 / F60 / F61, UNS S32750 / S32760 |

| Carbon Steel DIN Flange | ASTM A105 / A105N, ASTM A350 LF2, ASTM A694 F52 / F56 / F60 / F65 / F70 / F80, ASTM A216 WCB, DIN 1.0460 / 1.0402 / 1.0619, Die Steel, Mild Steel |

| Alloy Steel DIN Flange | ASTM A182 F5 / F9 / F11 / F12 / F22 / F91, AISI 4130 / 4140 |

| Nickel Alloy DIN Flange | Nickel 200 / 201, ASTM B564 |

| Monel DIN Flange | Monel 400 (UNS N04400), Monel K500 (UNS N05500), ASTM B564 |

| Inconel DIN Flange | Inconel 600 / 601 / 625 / 690 / 718 / 783 / X750, ASTM B564 |

| Incoloy DIN Flange | Incoloy 800 / 800H / 800HT (UNS N08800), Incoloy 825 (UNS N08825), Incoloy 925, ASTM B564 |

| Hastelloy DIN Flange | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X, ASTM B564 |

| Alloy 20 DIN Flange | Alloy 20 / 20Cb-3, Carpenter® 20, ASTM B462 |

| 254 SMO DIN Flange | SMO 254 / 6Mo, UNS S31254, DIN 1.4547, ASTM A182 |

| Copper Nickel DIN Flange | Copper Nickel 90/10 (C70600), 70/30 (C71500), UNS C71640, ASTM B61 / B62 / B151 / B152 |

| Copper DIN Flange | TP1, TP2, T1, T2, C10100–C12300, C14200–C17200, C21000–C71520, including C10930, C11000, C11400, C12000, C12200, C26000, C28000, C33000, C44300, C70600, etc. |

| Brass DIN Flange | Grades 3602, 2604, H59, H62, etc. |

| Aluminium DIN Flange | Aluminium Grades 5052, 6061, 6063, 2017, 7075, etc. |

| Titanium DIN Flange | ASTM B381 Gr.1 / Gr.2 / Gr.4 / Gr.5 / Gr.7, UNS R50250 / R50400 / R50550 / R50700 / R52400 / R53400 / R56320 / R56400 |

| Other Special Grades | Al6XN, Tin Bronze, Aluminium Bronze, Lead Bronze, Nimonic 75 / 80A / 90 |

International Flange Standards We Manufacture & Supply

DIN flanges are standardized flange types originally defined by the German Institute for Standardization (Deutsches Institut für Normung). These flanges are widely used in piping systems across Europe, Asia, and parts of the Middle East. They are designed to connect pipes, valves, and other equipment while ensuring a leak-proof seal.

Key features include:

- Metric-based dimensions suited for global systems

- Pressure ratings from PN6 to PN400

- Common DIN standards:

- DIN 2573 (Slip-On PN10)

- DIN 2633 (Weld Neck PN16)

- DIN 2527 (Blind Flanges)

- DIN 2501 (now replaced by EN 1092-1)

DIN flanges are used in:

- Water treatment plants

- Chemical processing units

- Oil & gas facilities

- HVAC and mechanical systems

These flanges continue to be in high demand for projects requiring legacy specifications or compliance with older system designs.

DIN flanges are available in a wide range of nominal pressure ratings, also known as PN (Pressure Nominale). These pressure classes define the maximum pressure a flange can withstand at a reference temperature.

Standard DIN flange pressure ratings include:

- PN6 – Suitable for low-pressure water and HVAC applications

- PN10 – Used in water distribution and basic fluid systems

- PN16 – Most commonly used in industrial pipelines

- PN25 & PN40 – For higher pressure in steam, gas, and chemical systems

- PN64, PN100, PN160, PN250 & PN400 – For specialized high-pressure systems

These PN ratings correspond to specific bolt patterns, gasket dimensions, and wall thickness, and are critical for ensuring compatibility and safety in design.

Selecting the correct DIN flange type depends on several technical factors, such as connection method, pressure rating, pipe size, and application environment. DIN standards specify multiple flange types, each with a unique function and construction.

Common DIN flange types and their use cases:

- DIN 2633 – Weld Neck Flange (PN16):

Ideal for high-pressure and high-temperature systems with butt-welded connections.

- DIN 2576 – Slip-On Flange (PN10):

Used for low-pressure pipelines where welding is done on both sides.

- DIN 2527 – Blind Flange:

Designed to seal the end of a pipeline or vessel, suitable for inspection and pressure testing.

- DIN 2566 – Threaded Flange:

Common in smaller bore connections without welding, often in water or compressed air lines.

- DIN 2642 – Loose Flange with Stub End:

Used where frequent dismantling is required, often paired with PTFE or other gasketed stub ends.

To ensure proper selection:

- Confirm PN rating (pressure class)

- Match face type (RF, FF) with gaskets

- Validate with material compatibility and standards

Yes, many DIN flange types are functionally compatible with EN 1092-1 flanges, as EN 1092-1 was developed to standardize and replace various national standards, including older DIN specifications.

Here’s how they relate:

- DIN → EN 1092-1 Equivalents:

- DIN 2633 ≈ EN 1092-1 Type 11 (Weld Neck)

- DIN 2576 ≈ EN 1092-1 Type 01 (Slip-On Plate Flange)

- DIN 2527 ≈ EN 1092-1 Type 05 (Blind Flange)

- DIN 2566 ≈ EN 1092-1 Type 13 (Threaded Flange)

- DIN 2642 ≈ EN 1092-1 Type 02 (Loose Flange with Stub End)

Compatibility Considerations:

- Dimensions may differ slightly, especially in bolt holes, flange thickness, or face finish tolerances.

- Ensure both flanges share the same PN rating (e.g., PN16) and face type (RF, FF).

- Gasket selection must also match the surface finish and pressure class of both flanges.

While they are generally compatible, consulting technical datasheets or a qualified engineer is advisable when mixing DIN and EN systems.

Selecting the right gasket is crucial to ensure a leak-proof and reliable seal in DIN flange connections. Gasket compatibility depends on the face type, pressure class (PN), fluid media, and temperature range.

Common gasket types used with DIN flanges include:

- Spiral Wound Gaskets (SWG):

Suitable for DIN flanges with raised face (RF) connections in high-pressure and temperature applications. Often used in petrochemical and power plants.

- Metal Jacketed Gaskets:

Used in steam lines and process industries, especially with DIN weld neck flanges.

- Flat Gaskets (Non-metallic):

Made from materials like EPDM, Graphite, PTFE, or CNAF, these are common with flat face (FF) flanges under moderate pressures (PN6–PN16).

- Ring Type Joint Gaskets (RTJ):

Though less common in DIN series, RTJ can be custom-fitted for special sealing needs.

Important Considerations:

- Match the gasket material to media compatibility (e.g., PTFE for chemicals, Graphite for steam).

- Ensure gasket dimensions follow DIN standards — DIN 2690 and EN 1514 are typically referenced.

- For PN ≥ 40, reinforced metallic gaskets are generally recommended.

Nutech Overseas is a trusted global supplier of DIN standard flanges, exporting high-quality forged and plate flanges that meet DIN and EN specifications to industries worldwide.

Our key export destinations include:

- Europe: Germany, France, Spain, Italy, Netherlands, Belgium, Poland, Czech Republic

- Middle East: UAE, Saudi Arabia, Oman, Qatar, Bahrain, Kuwait

- Africa: Egypt, South Africa, Nigeria, Morocco

- Southeast Asia: Indonesia, Vietnam, Malaysia, Philippines, Thailand

- South Korea & Japan

- South America: Brazil, Chile, Argentina

- Australia & New Zealand

Export Capabilities:

- Full compliance with EN 10204 3.1 / 3.2 certification

- Standard and custom packaging with third-party inspection (TPI) support

- Rapid logistics and documentation support for global project supply

Browse The Products

Forged Fittings

Flanges

Buttweld Fittings